Molybdenum est Refractorium metallum notum est insigni High-temperatus vires, humilis scelerisque expansion, et excellens corrosio resistente . Inter multas formas; Metal Molybdenum denudat Sunt late in industriae, aerospace, electronics et metallurgical applications debitum ad eorum facultatem ad resistere extrema condiciones.

Deligendo Molybdenum habena in summus temperatus applications, pluribus factores oportet diligenter aestimari curare Optimal perficientur, diuturnitatem et salus . Hae factores includit materia puritas, mechanica proprietates, scelerisque characteres, superficiem qualis, dimensional tolerances et compatibility cum operating environment. Hoc articulum explorat his rebus in detail, providente comprehensive ducem progenitores, gravida, et procuracionem elit.

I. intellectus metallum Molybdenum denudat

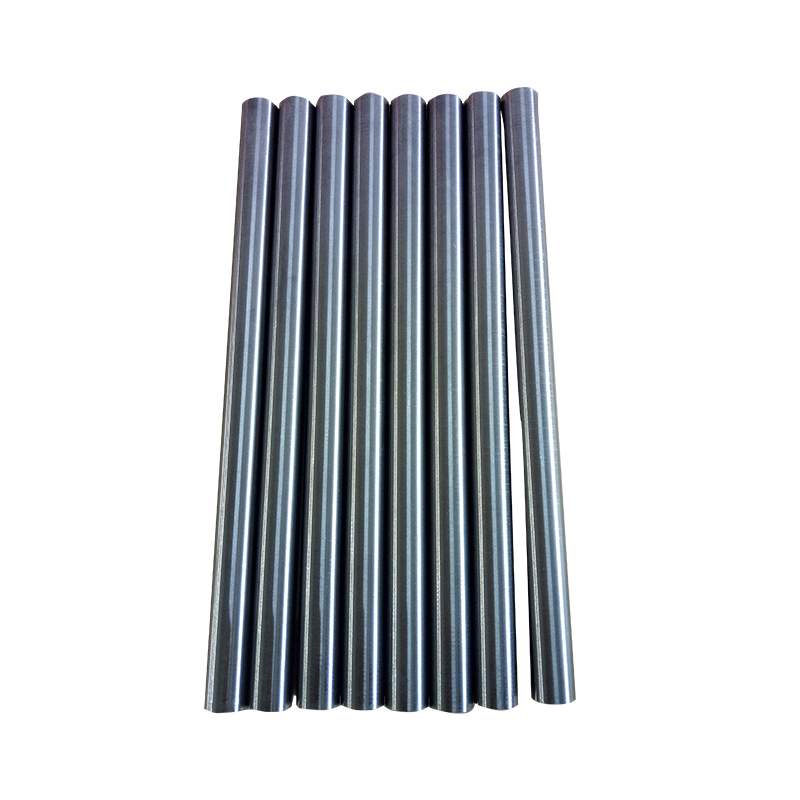

A Metal Molybdenum habena est plana, elongata forma Molybdenum produci per processuum ut Rolling, slitting, aut extrusionem . Haec denudat variantur crassitudine latitudine longitudo fretus in animo application.

Clavem proprietatibus, ut Molybdenum denudat specimen pro altus-temperatus environments includit:

- Altus liquescens Point: Proxime 2,623 ° C (4,753 ° F) , Permittens illud ponere structural integritas in extrema calore.

- Low scelerisque expansion: Minimal expansion reduces scelerisque accentus in praecisione components.

- Maximum scelerisque conductivity: Facilitates celeri calor dissipatio, utilis in electronic et industriae applications.

- Corrosio et oxidatio resistentia: Praecipue effective in vacuo vel regi atmosphaerae.

Ob haec proprietatibus, Molybdenum literature sunt in calefactio elementa, summus temperatus furnorum, electrica contactus, aerospace components et metallurgical applications .

II. Puritas et Alloy compositionem

In pudicitia de Molybdenum significantly afficit eius summus temperatus perficientur. Commercial Molybdenum typically ranges a 99.95% ad 99.99% puritatem , Minimal copia ferrum, Tungsten et aliis metallis.

Factors considerare de puritate includit:

- Impura: Elementa ut ipsum, oxygeni et NITROGENIUM potest formare oxides vel carbides ad altum temperaturis, comprominging vires.

- Alloying: Quidam applications ut requirere Molybdenum Alloys cum parva additiones Titanium, Zirconium, aut Hafnium ad amplio serpere resistentia, scelerisque conductivity, aut oxidatio resistentia.

Discriptis oportet gradu ensures Mechanica stabilitatem, oxidatio resistentia, et diu servitium vitae in extrema scelerisque conditionibus.

III. Mechanica proprietatibus

Summus temperatus applications imponere significant mechanica accentus , Inter tensile, compressive et serpat copias. Ideo intellectus mechanica proprietatibus Molybdeno denudat est crucial.

Key mechanica factores includit:

- Timnius fortitudinem: Molybdenum denudat debet resistere extendens aut trahens copias sine permanens deformatio.

- Cedite vires: Indicat accentus gradu quo habena incipit deforme plastrum. High cede vires est de necessitate vitare structural defectum.

- Repente resistentia: Termini refert ad tardus deformatio in longum differentur alta temperaturis. Maximum serpere resistentia necesse est applications sicut fornacis components et aerospace partes.

- Ductility: Licet Molybdenum est in sequebatur in cubiculum temperatus, eius ductility amplio cum elevatum temperaturis, faciens facilius ad formam vel convenire components.

Engineers oportet diligenter par Mechanica res requisita et operational temperatus et onus condiciones.

IV. Inrmal Properties

Inrmal performance is a primary consideration for molybdenum strips used in high-temperature applications. Important thermal factors include:

A. Scelerisque conductivity

High scelerisque conductivity concedit celeri calor translatio, ne localized hotspots et reducendo scelerisque lassitudine. Applications ut Electrical contactus et calor demergit prodesse significantly ex proprietate.

b. Thermal expansion coefficient

Molybdenum habet humilis coefficiens scelerisque expansion (~ 5.2 × X ^ -6 / ° F) . Hoc minimizes dimensiva mutationes sub fluctuans temperaturis, quod est discrimine in praecisione components et vacuo environments.

c. Summus temperatus vires

Molybdenum retinet Optimum vires usque ad 1,500-2000 ° C Faciens idoneam fornacem components, cruces, et erucae engine partes.

Discriptis a habena cum verificatur summus temperatus vires ensures Long-term stabilitatem et reducitur sustentacionem In extrema environments.

V. Superficiem species et metam

In PRO De Molybdenum literature afficit eorum perficientur in altum temperatus applications. Considerations includit:

- Superficiem lenitatem: Smooth superficiefice redigendum accentus concentratione, quae potest ad rimas vel immatura defectum.

- Oxide layers: Nimia superficiem oxidatio potest infirmare habena vel reducere scelerisque conductivity. Propriis repono in Vacuum aut inertem atmosphaerae Ante usum adiuvat ponere qualitas.

- Coatings: Quidam applications requirere Tutelaa coatings (E.G .: Nickel et Molybdenum Silicide) ad augendae oxidatio resistentia in aere ad elevatum temperaturis.

Ensuring excelsum superficiem qualis amplio diuturnitatem, salutem et efficientiam In postulant applications.

VI. Dimensional tolerances

Precise dimensiones sunt discrimine in applications in Molybdeno denudat oportet fieri intra stricta mechanica coetus. Considerations includit:

- Crassitudo uniformitatem: Variationes potest causare inaequale æstus distribution vel mechanica accentus.

- Width et planities: Extenditque oportet obviam exigere latitudine cubits et manere plana ad curare propriis installation et contactus cum aliis components.

- Longitudo consistency: Maxime momenti in automated productio lineae vel modularibus.

Saepe providere manufacturers TOLLITIUM tolerances Nam specialized applications ad curare et habena functionibus firmiter sub altum temperatus conditionibus.

VII. Environmental compatibility

In operating environment has a direct impact on the performance of molybdenum strips. Key considerations include:

- Atmosphaera: Molybdenum oxidizes ad altum temperaturis in aere. In applications ubi oxygeni est praesens, coatings, offering, aut inertem atmosphaerae Commendatur.

- Vacuum Conditions: Molybdenum performs exceptionally bene in vacuo aut imperium Gas ambitus, commune in electronics et aerospace applications.

- Patefacio ut Media: Quamvis repugnant multis oeconomiae, longum differentur nuditate ad certum metallis aut reactivum vapores potest necessitate tutela coatings.

Matching ad habena scriptor characteres ad environmental condiciones prohibet Degradation et defectum .

VIII. Compatibility cum fabricatione modos

Summus temperatus components saepe requirere additional Processing et Conventus . Molybdenum habena debet esse compatible:

- Cutting et slitting: Precisione secans ensures propriis dimensiones sine introducendis accentus rimis.

- Formatam et tendentes: Extenditque debet ponere structural integritas in figura.

- Welding et conjunctione: Molybdenum welding requirit summus temperatus ars et compatible filler materiae ad vitare fragtileness.

Intellectus fabricatio requisitis ensures habena praestat firmiter in ultima application.

IX. Cost et Availability Consensiones

Etsi perficientur est paramunt, Cost-efficaciam Relinquitur momenti factor:

- Material sumptus: High-puritas Molybdenum est magis pretiosa sed essential ad discrimine summus temperatus applications.

- Processing Custus: Certamini volvens, coating, et slitting potest crescere costs.

- Availability: Supplementum consistent Supple Supplementum grades impedit productionem moras in industriae aut aerospace projects.

Balls perficientur et pretium adiuvat eligere aptissima habena ad intendebat usum.

X. Applications de Molybdenum denudat in altum temperatus environments

Metal Molybdenum denudat Sunt late usus est in applications quod demanda extrema æstus resistentia:

- Aerospace: Components in jet engines, erucae nozzles et scelerisque clypeum.

- Electronics: Calor submittit, vacuo fistulam partes et electrica contactus.

- Metallurgy: Fornacem grids, cruces et altus-temperatus formam.

- Industrial vestibulum: Calefactio elementa, sensoriis et summus temperatus scutulis.

- Energy Industry: Components in nuclei reactors et solaris scelerisque collectores.

Quisque applicationem requirit diligenter statera scelerisque, mechanica et environmental proprietatibus , Illuminare momentum propriis habena lectio.

XI. Genus eligens a lacerna

Simplify in selectio processus, engineers debet considerare sequenti maculosus:

- Puritas materiales: ≥ 99.95% ad altus-temperatus stabilitatem.

- Mechanica Properties: Adaequabitur tensile viribus, cedere vires, ductility, et reptant resistentia.

- Inrmal Properties: Maximum scelerisque conductivity, humilis scelerisque expansion et summus temperatus vires.

- Superficies species: Smooth, uniformis et optionally iactaret oxidatio resistentia.

- Dimensional accurate: Consistent crassitiem latitudine glacies et longitudo.

- Environmental Compatibility: Suitability in vacuo, aere, aut mordive atmosphaerae.

- Fabrication Requisita: Compatibility cum secans, inclinans et welding processibus.

- Sumptus et Availability: Libra perficientur cum budget et suppleret stabilitatem.

Conclusio

Lectio a Metal Molybdenum habena Nam summus temperatus applications est complexus processus quod requirit diligenter consideratione Materia puritate, mechanica et scelerisque proprietatibus, superficies metam, dimensional praecisione, environmental compatibility, fabrication modi, et sumptus .

Perfaluating haec factores, engineers et designers potest ut electi Molybdenum habena performs firmissime sub extrema condiciones, maintaining structural integritas, scelerisque stabilitatem, et longa-term diuturnitatem. Ex aerospace et electronics ad metallicy et industriae calefactio, ius Molybdenum habena est Planta operational salutem efficientiam .

Profectus in materia scientia, praecisione vestibulum et tutela coatings permanere expand ad capabilities de Molybdenum denudat, faciens eos in necessitate electionis est summus temperatus industriae applications Worldwide.